Supply Chain Management Consulting

Supply chains have experienced increased pressure and focus during the last 18 months or so. The impact of the global pandemic, Suez canal blockage, and Brexit in the UK and Europe has heightened awareness on supply chains and how fragile today’s globally connected supply chains are to unforeseen events. These current supply chain risk topics are in addition to threats from geopolitical issues that spread across countries or regions, natural disasters, industrial or strike action, sanctions, fires, or insolvency of a supplier or their sub-suppliers. Such disruptions can have a significant impact by triggering contractual penalties, negative customer experience, drop in revenue, or reputational damage.

The pandemic and societal changes have placed greater significance on the importance of well-understood global supply chain management. Consumers expect products and services to be available and dispatched the same day, but for these products to also be ethically sourced with minimal environmental impact.

These demands are somewhat opposed, however, knowing and mitigating the risks in your supply chain and being fully cognizant that your suppliers and their supplier are aligned with your corporate identity and goals are increasingly important.

Supply Chain Risk Management Assessment

Supply chain risk management is the process of monitoring, identifying, assessing, and mitigating risk in your supply network — in collaboration with your suppliers.

Our experienced team can help you implement effective, sustainable improvements to your supply chain risk management strategy and enable you to proactively assess your supply chain risk. Our consultants are experienced in supply chain risk assessments, helping you to identify, catalogue, and rank supply chain risks and suggest mitigation strategies and actions.

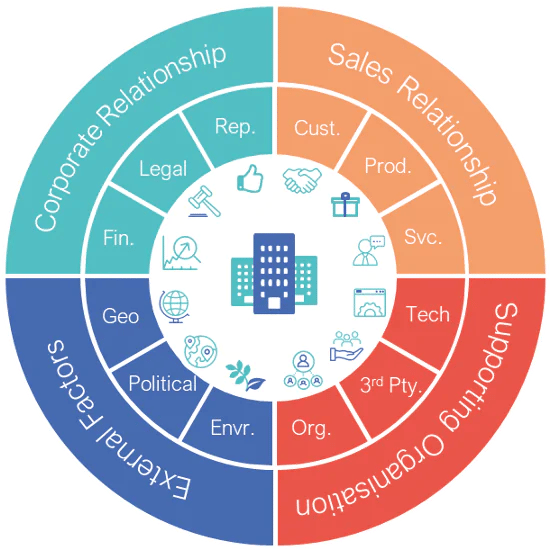

Our consultant-led risk assessment method evaluates risks within four towers; Corporate Relationship, Sales Relationship, Supporting Organisation, and External Factors.

The approach is based on a 3-stage process which first analyses the supplier influence in terms of impact on revenue, profitability, and/or outputs, then assesses the probability and impact of supplier risks across a range of critical business dimensions, and finally aggregates the risk rating of all suppliers across these dimensions to provide a consolidated supplier vulnerability assessment for your organisation.

The assessment output is tailored to your organisation’s needs and provides insight at an aggregate, individual supplier, and/or supplier dimension level. This insight provides the critical foundation for mitigation plans. The approach is supported by a flexible toolset that streamlines the process.

Supply chain risk management is not just about identifying and avoiding problems. It can also drive direct and measurable value by improving business continuity, provide greater supply chain visibility, strengthen supplier relationship management, improve regulatory compliance, and enhance corporate social responsibility (CSR) goals.

Avoiding Common Supply Chain Risk Mistakes

Our method can help implement changes in the supply chain risk management approach to mitigate common mistakes.

Mistake 1: Focusing risk efforts only on top tier suppliers

Many companies focus risk effort on their top suppliers (by value) and thus on the suppliers where the chance and impact of disruption would be most severe. However, risk management should consider against all active suppliers. A major vulnerability in many supply chains are suppliers who provide a small amount of specialised components or services. Even though the purchase value is small, disruption of these supplies can result in major delays or service disruption.

Mistake 2: Assessing suppliers only during onboarding

Evaluating suppliers during onboarding is an important step, however inevitably things will change. Suppliers can face financial problems, or industrial action, also, the likelihood of a natural disaster might increase due to changing climate conditions. Or the supplier’s own internal strategy might increase your reputational risk. Therefore, it is important to periodically assess your supply chain, capture risks and implement appropriate mitigating actions.

Mistake 3: Relying on past experience

Long-term supplier relationships may have a lower risk, but they are still open to risk. For example, your trusted supplier may open new facilities, change location or negotiate new contracts with their sub-suppliers. Each change introduces new risks to your supply chain. Again it is important to re-assess your supply chain and not to assume a long-standing supplier will never let you down.

Mistake 4: Failing to consider sub-suppliers

Often companies know who delivers goods or services directly to them, especially their key suppliers. But they do not know or risk assess the secondary or sub-suppliers to that supplier. Should disruption arise in this organisation, then the knock-on impact may affect your services. Therefore, it is important to understand the full supply chain and what measures your suppliers are taking to manage and mitigate risk in their supply chain.

The use of a Vendor Management tool such as Brooklyn Vendor Assurance (BVA) can help automate some of the supply chain risk activities and ensure your risk mitigation policy is applied and enforced by the vendor management team.

What are the benefits of specialist supply chain consultants?

Our expert consultants have many years of experience and can leverage a large repository of reference clients and engagements bringing the following benefits:

- a library of best practice tools and content

- subject matter expertise in a wide range of industry sectors and technologies to hit the ground running

- industry insight, we know what is standard and what is not

- pragmatic, balanced approach

Why Peru Consulting for Supply Chain Management Consulting?

As one of the leading supply chain management companies, Peru practitioners are service and supply chain experts and specialise in helping our clients from all sectors and industries successfully manage, leverage value, and pro-actively govern their third-party arrangements. Our people reflect our values, and we guarantee a collaborative, quality, agile, and trusted service. As Peruvians, we differentiate ourselves through our “Triple-A” consulting principles: Accelerate – Identify and deliver value early, Assure – the right things and provide certainty and Augment – be a part of the team and hit the ground running.